To dress cows for energy, to dress the climate crux! by Kiwaho Lab Inc.

Pitch

Do you know: 1 cow or horse = 1000 watts heater? 1 cow emission of methane 70 and 120 kg per year? heat stress is the biggest threaten?

Description

Summary

Large size livestock animal, such as cow and horse, emits significant heat energy all time.

Studies show that one cow is equivalent to a heater of 1kw to 1.5kw, average 1.2kw, and the said thermal energy is mostly dissipated by radiant and convection (about 70%), the other 30% by water vapor.

The insensible vapor loss via skin pores is about equivalent to 6.2 liters water per day. The urine water loss is about 15 liters per day.

Because the enthalpy of vapor is far bigger than water, so the less vapor still carries more heat than the large volume urine.

The 30kg/day manure alone constitutes another significant bio-chemical energy that can be extracted by anaerobic digester.

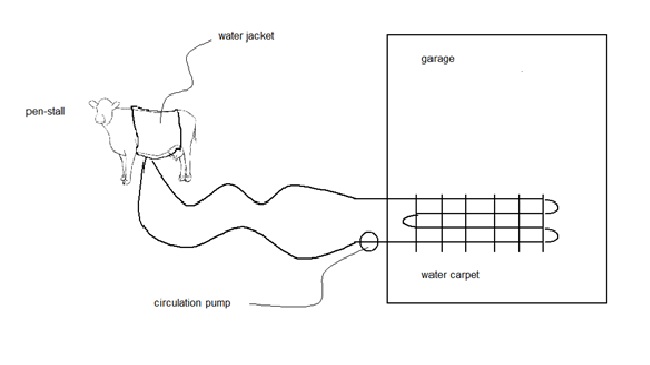

An innovative device of water jacket can work both as animal clothes and thermal collector.

The water jacket is designed in sandwich structure with hoses of interface for outside water circulation. It embraces the torso of large livestock, such as cow or horse.

Animals are penned on an open camp or uninsulated tie-stall barn.

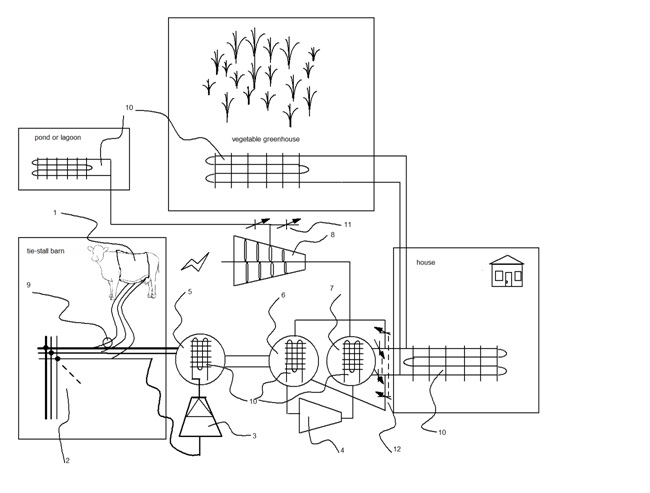

All hoses are hooked to a pipe matrix that is systematically connected to a barn-side water tank and vapor compressor.

Another building-side water tank is used to store higher temperature water that is the direct heat source of a radiant floor heating system.

The heat pump draws heat from barn-side warm water tank, and discharges heat to building-side water tank, then supports radiant floor heating system in winter or heat engine power plant in summer.

Water jack can also relieve the animal heat stress, because water is cooler than ambient air during hot season.

1 cow = 1000 watts, 1000 cows = 1MW.

As a good side-effect, the herd dressed in sexy colorful thermal coat will also stimulate higher reproduction and more milk production, and comfortable living can reduce the methane emission too.

If this patent-pending invention is broadly applied, an new category of industry will be born: cow garment, and this can boost economics!

Let’s scavenge this amazing free renewable energy!

Which proposals are included in your plan and how do they fit together?

The simplest rural garage space heater!

The heat and power co-generation system for a dairy farm with parasitic greenhouses vegetable-plant.

The heat engine can be the type of organic Rankine-cycle. Our laboratory can also provide more advanced patent-pending proprietary ejector based heat engine.

This technology can be combined with methane rich fart-gas collection backpack and/or the anaerobic manure methane gas station.

Explanation of the emissions scenario calculated in the Impact tab

Assuming the energy conversion efficiency of heat to work is 30%, 1kwh heat can be converted to 0.3kwh electricity, and 1kwh electricity production is equivalent to 0.523kg CO2 emission.

1 cow can generate 24kwh heat per day, so if we can make use of the cow power, then we can reduce carbon emission 24*0.3*0.523= 3.77kg CO2 per day, or theoretically 1.4 tons per year.

Considering in winter time, half of generated heat should be detained for cow survival, and not significant surplus, so the above data should be discounted to about 1 ton per year.

As per USA statistic data, the total inventory of milking cows in 2015 is about 9.3 million heads. That amount does not include beef cattle and horses, otherwise it may count to 98.4 million heads.

The CO2 emission in China is about 5000 million tons annually, so if this simple technology is widely applied, it will reduce about 2% CO2 emission.

What are the plan’s key benefits?

1. rural homestead can benefit from elimination of outsourcing energy, and implement autonomous energy self-supply.

2. some remote countryside may lack of electricity supply. Our second phase of plan will generate electricity by converting low grade heat to shaft work to drive generator.

What are the plan’s costs?

The main materials of water-jacket are rubber and fiber. One piece cost is less than $100.

The negative side effect is that cows can not run too far, and basically only a small tie-stall pen tolerable to prevent from hose kinking.

By using plugable hose connector, farmer can easily detach the water-jacket hoses for release of cow.

We are still seeking further improvement for the cow heat energy conversion.

What are the key challenges to enacting this plan?

Cow garment industry is absent until nowadays. So this new industry should be established from scratch first for the successive cow power harvest application.

Animal welfare activists may be over-reacted to this new invention. But detail scientific analysis can address their concerns.

Funding is also very important. We are seeking $500,000 to build a pilot project.

Timeline

now to 2016 Contract one OEM factory to product the water-jacket for different size cows, horses.

2016-2017 the first batch of water-jacket product ready, 1000 piece at first batch.

2017-2018 establish 2 kinds of typical pilot projects in China market: 1 to 5 cows application with only heat harvest for small space heating; 6 to 30 cows application with only heat harvest for whole household hot-water supply and winter heating, with surplus heat to heat small outbuilding or barn;

2018-2019 establish pilot projects for 31 to 150 cows for business facility heat supply in different selected provinces or districts. this is more typical configuration in USA or north America.

This schedule can be advanced 1 or 2 years for north America market.

2019-2020 establish 100kw- 1MW pilot projects for generating electricity, or with greenhouse vegetable business integration.

It can also be combined with the anaerobic methane gas station.

This schedule can be advanced 2 or 4 years for north America market.

Related plans

1. ejector based heat engine is parallelly developed.

2. X-vapor project that utilizes the evaporation energy absorbed from ambient background heat or solar irradiation.

All above plans involve our other patent pending technologies.

References

Managing Heat Stress in Dairy Cows

http://www.nadis.org.uk/bulletins/managing-heat-stress-in-dairy-cows.aspx

This Is How You Turn Cow Fart Gas Into Energy

http://bigthink.com/design-for-good/this-is-how-you-turn-cow-fart-gas-into-energy

National Agricultural Statistics Service - cattle inventory

http://usda.mannlib.cornell.edu/usda/current/Catt/Catt-07-24-2015.pdf

U.S. Equine Populations

http://www.igha.org/equids02.html

简讯:千瓦厚实验室发明牛马可穿戴水夹克热功联产系统装置