Solar Klin by naresh

Pitch

Wood drying reduces the moisture content of wood before its use.

Description

Summary

A solar kiln is the simplest and safest way to dry green wood quickly. After the kiln is loaded, all that’s required is some minimal vent adjusting while the wood dries. No sweating over daily drying rates and continual monitoring of the drying process.

Kiln design

Kiln is designed to hold about 300 bd. ft. that dictates a roof area of about 30 sq. ft., not including overhangs and framing that will block solar gain.

Too much solar-panel area and run the risk of drying the wood too fast; not enough and never get the wood to dry below 15 percent moisture content (MC).Installed a single fan rated at 1,000 cubic feet per minute (cfm) to circulate air through the stack of wood.

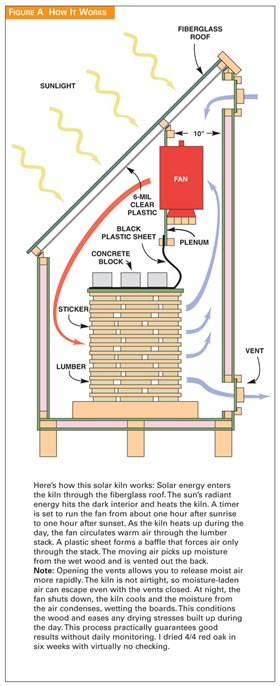

To calculate the size of fan needed (in cfm), multiply the number of sticker layers by the length in feet of the wood stack times the thickness in feet of the stickers (3/4 in. equals 1/16 ft.) times 150 fpm. A typical load of 4/4 wood in kiln has 14 layers x 8.5 ft. x 1/16 ft. x 150 fpm, which equals approximately 1,100 cfm. The fan is mounted high where it can push the hot air down through the stack. Roof angle is important. Determine latitude; then use that latitude number, plus or minus 5 degrees, for the kiln roof’s pitch.

Build the kiln

The kiln is made up of six panels (floor, roof, front, back and sides).Insulation in the walls and floor helps the kiln retain heat, which helps speed the drying process. All of the interior surfaces are coated with a flat black oil-based paint. The oil base prevents moisture from penetrating into the wood, and the flat black color absorbs heat from the solar energy. The solar-panel roof is made with translucent corrugated-fiberglass roofing material. It offers the best combination of low cost and durability. To increase the insulating value of the roof, also stapled clear 6-mil-thick plastic sheeting on the underside of the roof frame. This added layer greatly improves the kiln’s performance.

Category of the action

Adaptation

Who will take these actions?

Government,NGOs and INGOs

What are other key benefits?

- Promote a shift to cleaner fuels and renewable energy

- Reduction of the green house gas

- Healthy Environment

What are the proposal’s costs?

Solar klin cost in perspective of Nepal $500/-

Time line

Within 1 month solar klin installation.

Related proposals

References

http://www.bertieswoodfuel.co.uk/kiln-drying