Pitch

Rotor engine fuel consumption is high, high speed, torque small, driving it with the explosion for power generation.

Description

Summary

The rotary combustion engine

https://www.youtube.com/watch?v=6BCgl2uumlI

Disadvantages of the rotor engine: 1: high fuel consumption, 2: high speed, but torque is small, start to speed up the weakness.

Disadvantages of the rotor engine: 1: high fuel consumption, 2: high speed, but torque is small, start to speed up the weakness.

This project is aimed at the above problems by combining the explosive power and the rotor engine.

Rotor engine fuel consumption is relatively large. the rotor engine combustion chamber shape is not conducive to complete combustion, with high rotor speed, flame propagation path is relatively short, making fuel consumption increased.

The explosive power can solve the fundamental problem of the rotor engine, the explosion speed is over 2000 m / s, it is much higher than the burning speed of 30 m / s, making the rotor engine has been deflated finished when it reaches the exhaust outlet station.

To solve the high temperature problem released during the explosion process, this project increases the water cooling process, add a water nozzle, water vapor discharge steps. While reducing the rotor engine speed. Sprinkler purposes are cooling the rotor, cooling the rotor cavity. Its expansion can also work done.

At the same time, in order to reduce the negative pressure on the engine reverse obstruction, increase a natural suction process, the role can also pre-cooling the rotor and rotor cavity.

Project Purpose used for power plant engines.

Is this proposal for a practice or a project?

Project

What actions do you propose?

1.Historical Review

(1)In 1960, Wengkel announced to the world this subversive imagination of the new internal combustion engine --- rotor engine.

(2) In 1963, Mazda established the "Rotor Research Department", and appointed Yamamoto Kenji led a well-selected 46 engineers for rotor engine research and improvement, which 47 people also known as "rotor 47 warriors."

(3) Historically, Mazda was the sole Asian carmaker to win the 24-hour endurance race at Le Mans. Throughout the history of Le Mans contest, the first 58 championships were European and American riders monopoly. In 1991, Mazda R26B 2.6L (0.654L * 4) four rotor engine 787B racing cars won the championship with the first two laps of the great advantage.

2. The advantages and disadvantages of the rotor engine

A. Advantages

The entire rotor engine has only two rotating parts (eccentric shafts and rotors) at work, which simplifies the structure of the engine, which is smaller and lighter than the average four-stroke reciprocating engine. The failure rate also cut back.

In addition, since the rotor engine does not reciprocate, it does not require a precise crankshaft balance to achieve a higher speed, and its speed is faster than the reciprocating engine

As the eccentric shaft speed is always three times the rotor speed, when the rotor engine up to 9000rpm, the triangular rotor is only 3000rpm, compared to the reciprocating piston engine 9000rpm, the piston up and down 9000 times every minute, Equivalent to the piston to complete 300 strokes per second, which also makes the rotor engine can easily get a higher speed.

B. Disadvantages

Because the burning time is short, and the mixture combustion is not complete, while the work trip eccentric shaft is only half the angle of the piston reciprocating engine, so the rotor engine fuel consumption is much higher than the traditional internal combustion engine, and the rotor engine start and low speed will be discharged a large number of hydrocarbons?

In addition, the ignition system is also one of the weaknesses of the rotor engine, because its combustion chamber are in the mobile operation, the process of explosion flame propagation mode is not ideal, which also put a higher demand for the ignition system, not only to improve Ignition energy, while ignition timing and spark plug position is also very important.

See Explode Engine project for the explosion

3. Explosive Rotor Engine Type A- Simply explode

A. Workflow by the following steps:

1. Fuel nozzle spray explosive mixture;

2. Compress the explosive mixture;

3. Detonator ignition detonated explosive mixture;

4. Emissions of explosives.

4. Explosive Rotor Engine Type B- with water spray cooling

Rotor engine installation improvements include: increasing water nozzles, naturally aspirated imports. Follow these steps:

1.Feed port injection explosive composition;

2. Compressing the explosive composition;

3. Detonator detonated explosive mixture;

4. Exhaust emissions of explosives;

5. Intake air inhalation;

6. The intake air is compressed;

7. Sprinkler water spray water and evaporate expansion;

8. Discharge of water vapor.

The above is a single cycle of water cooling, three rotor surface of the ignition 1, water 1 times, the interval can also be adjusted, such as double circles ignition.

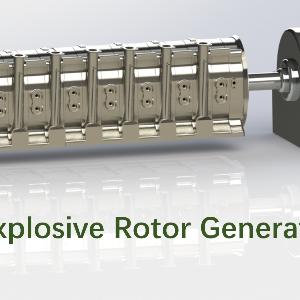

4. Rotor series arrangement

Series rotor engine eccentric shaft, rotor assembly diagram and rotor engine transfer diagram.

The triangular rotor engine is used power plant engines, which have 8 rotor engines, which are arranged in parallel, to drive the generator together.

The triangular rotor engine is used power plant engines, which have 8 rotor engines, which are arranged in parallel, to drive the generator together.

The triangular rotor engine unit consists of at least four groups, optimized selection of 12 or 24 groups.

The triangular rotor engine unit consists of at least four groups, optimized selection of 12 or 24 groups.

5. Explosive fuel

Including: Pulverized coal and oxygenated air compositions, natural gas and air compositions, biomass and oxygen-enriched air compositions, fuel oil vapor and oxygen-enriched air mixtures; flammable vaporized gas and air mixtures; flammable liquid vapor with air mixture

The first choice of biomass fuel powder or fiber filament can be used as a kind of fuel, including but not limited: biomass fuels, traditional gasoline, diesel, kerosene, liquefied petroleum gas, natural gas and even coal gas, coal powder and even gunpowder, explosives and so on.

Dust comes from straw, fruit shell, weeds, leaves and other grinding products, wheat flour, sugar, wood chips, dyes, wood, tea powder, tobacco powder, starch and so on.

According to the different dust material, the particle size range of the powder is very large (3um ~ 100um).

6. Auxiliary blast gas

It may be air, preferably oxygen-enriched air, or whole oxygen.

Who will take these actions?

1.Start-up companies,build a team.

2.Partner with universities, we may be able to accelerate the research, development, and prototyping phases by collaborating openly with universities.

3. Energy companies

Where will these actions be taken?

American, Japan, Germany.

Research and Development - the author is currently seeking initial private investors to provide funding for research and development.

In addition, specify the country or countries where these actions will be taken.

No country selected

Country 2

No country selected

Country 3

No country selected

Country 4

No country selected

Country 5

No country selected

Impact/Benefits

What impact will these actions have on greenhouse gas emissions and/or adapting to climate change?

1. The project can provide an optimal way of solar recycling, namely

2. This project provides a method for low-energy waste such as straw, hull, weed, and leaves to produce high power with the aid of oxygen-enriched air or especially oxygen.

3. Refining the use of fuel: fuel particles up to the micron level, far less than the pulverized coal, so people can use oxygen to improve energy efficiency.

Sunlight and carbon dioxide in the air make straw, shell, weeds, leaves and other C elements by the photosynthesis;

While generating oxygen O2 elements;

These straws, hulls, weeds, leaves and other C elements and oxygen O2 produce energy and carbon dioxide by the explosion;

Its nature is also solar energy.

What are other key benefits?

1. Power plant pulverizer homemade fuel: power plants can buy their own crusher, dry and broken biomass fuel, used to drive the generator, no need to rely on fuel companies, such as coal mines.

2, oxygen equipment industry ushers in development opportunities.

Costs/Challenges

What are the proposal’s projected costs?

A. Cost reduction factors

1, explosive expansion work

2, oxygen heat

3, direct drive

4, water vapor expansion work

B. Cost increase factor

1, oxygen preparation energy consumption

2, fine powder grinding energy consumption

Timeline

1. Argument: 1 year

2.Design: 6 months

3. development: 6 months

4. Demonstration project: 2 years

5. Promotion and application: 1 year

About the author(s)

Related Proposals

References

1.US7784435B1

2.CN2688901Y

3.CN1262747C

4.CN202325829U

5.CN1341805A

6.CN1514121A

7.CN102719261A

8.CN201310314729.1